Best China Triple Silver Low-E Glass Suppliers - Energy Efficient Low-E Coated Glass – Jinjing

Best China Triple Silver Low-E Glass Suppliers - Energy Efficient Low-E Coated Glass – Jinjing Detail:

Why Choose Low-E glass? How does it save energy?

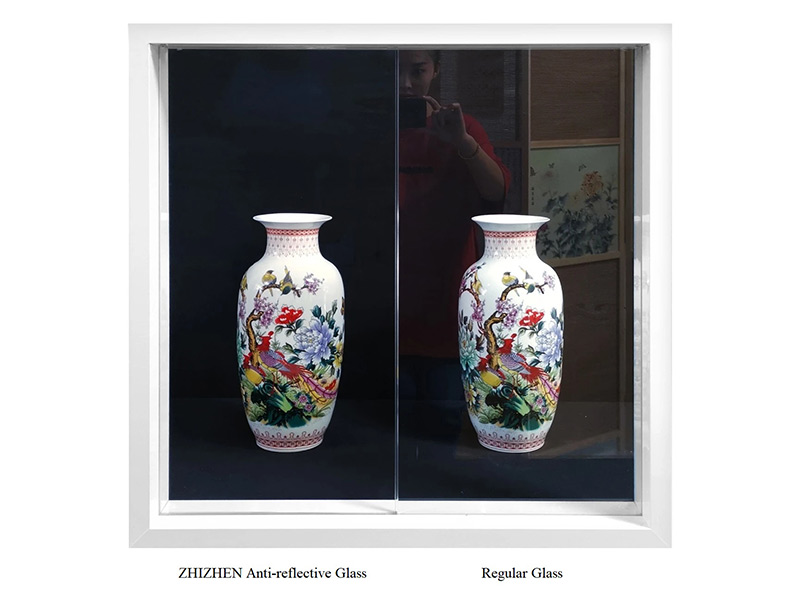

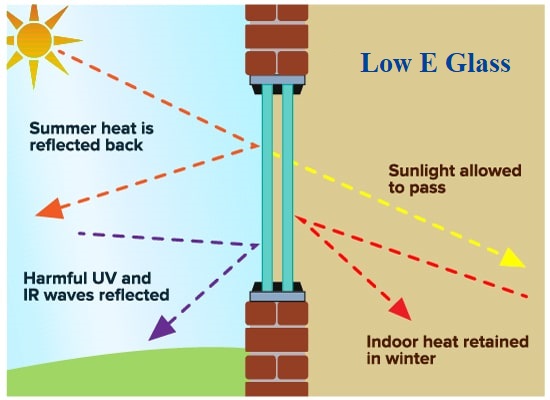

Low-E glass refers to glass with a low emissivity coating. It reduces heat gain or loss by reflecting long-wave infrared energy (solar heat), therefore decreases the U-value & solar heat gain and improves the energy efficiency of the glazing. Because of its relative neutrality in appearance and energy efficiency, low-E glass is widely used in residential and commercial buildings and is expected to continue to increase in usage in the coming years.

What’s the difference between soft coated and hard coated Low-E glass?

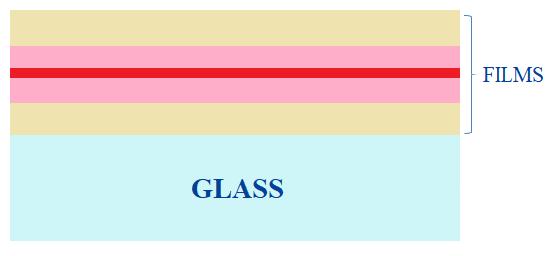

Low-E glass is made of low emissivity coating film on the surface of glass by physical or chemical methods. At present, the mature technologies for commercial manufacturing of Low-E glass include vacuum magnetic emission (physical method, also called offline Low-E glass & soft coated Low-E glass) and chemical vapor spraying process (chemical method, also called online Low-E glass & hard coated Low-E glass).

| What’s the difference between soft coated and hard coated Low-E glass? | ||

| ITEMS | soft coated | hard coated |

| Production Process | 1. Vacuum magnetic sputtering emission 2. Completed in an independent coating glass production line 3. Multilayer composite coatings on glass surface |

1. Chemical vapor deposition 2. Finish coating in tin bath of float line 3. Single layer coating |

| Film Structure |  |

|

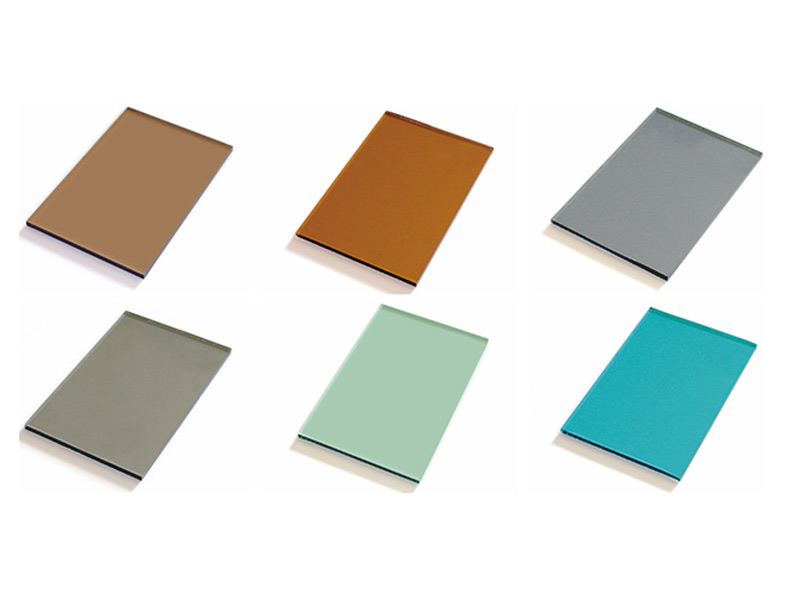

| Variety of Appearance & Performance | Rich product series: large selection range of appearance color and performance data | The product series is simple: the appearance color and parameter are relatively fixed with limited selectivity. |

| Film Stability & processability | 1. The film is easy to be oxidized and can be stored for 1-2 years after professional packaging; 2. It can’t be used in a monolithic piece, it must be used after insulating, and the coating is in the insulated cavity; 3. Special case: Jinjing triple silver products can be used in laminated glass , and the coating can contact the coating directly |

1. The coating is sintered with glass, which is very hard and stable. It is stored as common float glass; 2. It can be used in a monolithic piece; It is easy to be processed and the processing method is the same as ordinary float glass |

| Jinjing Star Products | US1.16, UD49, UD68, UD80,SOLARBAN70, SOLARBAN 72 | EazyTek |

What’s the differences of triple, double, single silver low E glass?

Are you still confused?

What’s the differences of triple, double, single silver low E glass?

How can I choose?

Follow me.

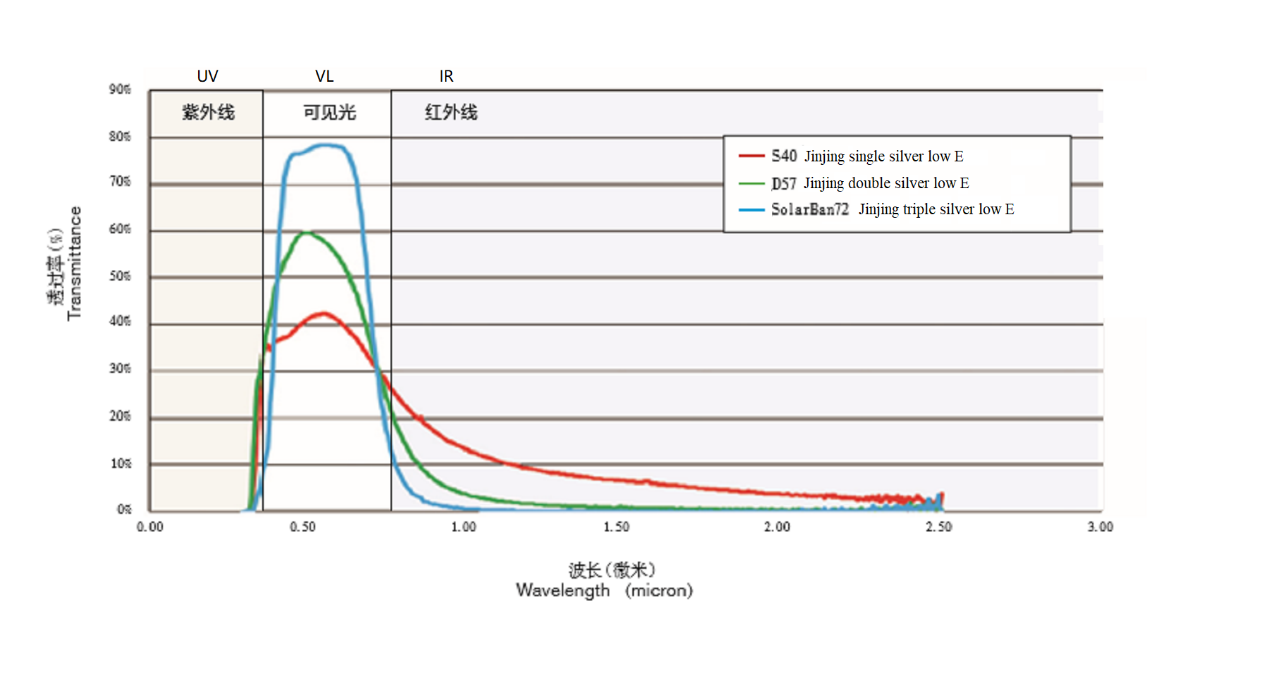

In the graph, these are three solar spectral transmittance curve of triple, double, single silver Low-E glass with similar visible light transmittance. The middle area of the vertical line is the area of visible light (380-780 nm), and the visible light transmittance of the three kinds of Low-e is similar. The right area of the vertical line is infrared ray area (780-2500 nm). Since most of the heat is carried by infrared rays, the area under the curve reflects the heat energy which the solar energy goes directly through the glass. The single silver Low-e contains the largest area, double silver Low-E takes second place, and the triple silver Low-e takes the smallest area which means the least heat goes through the glass, and best thermal insulation performance.

In the graph, these are three solar spectral transmittance curve of triple, double, single silver Low-E glass with similar SHGC value within 380-2500 nm. The SHGC value is similar, which means the contained area of the three coated glass is similar, but the distribution shape of the curve is obviously different, and the triple silver Low-e takes the smallest area which means the least heat goes through the glass. With similar SHGC value, the triple silver Low-e shielding capability of infrared thermal radiation is much greater than that of double silver and single silver Low-e glass, which greatly improved the indoor comfort in summer.

Why choose Jinjing Low-E Glass?

1. Technology advantage:

World-leading technology from PPG America.

Unique resource of professional coating experts in glass industry.

Strong technical service team for customer support.

2. Performance advantage:

First manufacturer in China to supply off-site temperable triple silver Low-E, LSG reach 2.32.

IGU visible light transmission 82%, highest in the market.

IGU U-factor reach 1.01 W/m2.K, lowest in the market.

3. Industry advantage:

The richest product structure, whole industry chain from clear float glass, various tinted glass, ultra clear glass to complete product solutions for customers.

Optical Parameters

Soft coated series

|

No |

Description |

Visible Light(%) |

Solar Energy(%) |

NFRC |

||||||

|

Trans(%) |

Reflectance(%) |

Trans |

Refectance |

U-Value |

Sc |

SHGC |

||||

|

Out |

In |

Winter |

Summer |

|||||||

|

1 |

6mmS1.16+12A+6mmClear |

80 |

13 |

13 |

50 |

24 |

1.72 |

1.65 |

0.65 |

0.57 |

|

2 |

6mmUS1.16+12A+6Ultraclear |

83 |

14 |

14 |

60 |

30 |

1.73 |

1.70 |

0.71 |

0.61 |

|

3 |

6mmD80+12A+6Clear |

70 |

13 |

13 |

33 |

34 |

1.70 |

1.34 |

0.43 |

0.37 |

|

4 |

6mmUD80+12A+6Ultraclear |

73 |

13 |

14 |

38 |

41 |

1.66 |

1.60 |

0.45 |

0.39 |

|

5 |

6mmD68+12A+6Clear |

60 |

17 |

20 |

33.5 |

22.0 |

1.71 |

1.67 |

0.46 |

0.40 |

|

6 |

6mmUD68+12A+6Ultraclear |

63 |

18 |

21 |

39.7 |

27.9 |

1.71 |

1.67 |

0.50 |

0.43 |

|

7 |

6mmD49+12A+6Clear |

46 |

15 |

13 |

21 |

32 |

1.69 |

1.64 |

0.29 |

0.25 |

|

8 |

6mmUD49+12A+6Ultraclear |

48 |

15 |

13 |

23 |

44 |

1.69 |

1.64 |

0.30 |

0.26 |

|

9 |

6mmSolarban70+12A+6Clear |

64 |

12 |

13 |

24 |

50 |

1.62 |

1.55 |

0.31 |

0.27 |

|

10 |

6mmSolarban72+12A+6Ultraclear |

71 |

13 |

14 |

28 |

53 |

1.62 |

1.55 |

0.34 |

0.30 |

| Notes: 1. Above performance data are calculated according to stadards NFRC 2010, EN673 and JPG151. 2. The performance data are only for reference. Jinjing will hold the right of final interpretation. |

||||||||||

Hard coated series

|

TEK6 |

TEK10 |

TEK15 |

TEK35 |

TEK70 |

TEK250 |

Instrumentation |

||

| Thickness | 4mm、3.2mm± 0.1mm | 4mm、3.2mm± 0.1mm | 4mm、3.2mm± 0.1mm | 4mm、3.2mm± 0.1mm | 4mm、3.2mm± 0.1mm |

4mm、3.2mm±0.1mm |

Micrometer |

|

| Visible Light Transmittance |

≥80% |

≥82% |

>83% |

≥83% |

>83% |

>83% |

Hazegard |

|

| Coating Reflectance |

≤11% |

≤11% |

<12% |

<12% |

<12% |

<12% |

HunterLab |

|

|

Haze |

≤5% |

≤1.7% |

≤1% |

<1% |

≤1% |

≤1% |

Hazegard |

|

|

Sheet Resistance |

Before temper |

6-8Ω/■ |

8.0-9.5Ω/■ |

12-14Ω/■ |

34-38Ω/■ |

60-68Ω/■ |

260-320Ω/■ |

Four-point probe /Nagy Sheet Resistance Meter |

| After temper |

6-8Ω/■ |

9.0-10Ω/■ |

12-14Ω/■ |

38-40Ω/■ |

64-72Ω/■ |

252-300Ω/■ |

||

|

E-value |

<0.10 |

<0.12 |

<0.15 |

<0.35 |

<0.45 |

<0.67 |

||

| Color Uniformity |

ΔE*ab≤0.8 |

ΔE*ab≤0.8 |

ΔE*ab≤0.8 |

ΔE*ab≤0.8 |

ΔE*ab≤0.8 |

ΔE*ab≤0.8 |

1 pcs glass |

|

Certificates

Applications & Projects

Project Name: The Exchange-106

Location: Malaysia

Glass: 8mm UD80 7000㎡for podium structure

Project Name: Oracle office Texas

Location: USA

Glass: 10mm Solarban 72 jumbo size

Project Name: Waldorf Astoria

Location: USA

Glass: 6mm, 10mm Solarban 72 2000㎡ for curtain wall

Project Name: Nikko Toshogu (400 Anniversary Project)

Location: Japan

Glass: 10mm US83 1000 ㎡ for curtain wall

Product detail pictures:

Related Product Guide:

We keep on with our business spirit of "Quality, Performance, Innovation and Integrity". We goal to create much more worth for our customers with our rich resources, state-of-the-art machinery, experienced workers and exceptional providers for Best China Triple Silver Low-E Glass Suppliers - Energy Efficient Low-E Coated Glass – Jinjing , The product will supply to all over the world, such as: Bolivia, Salt Lake City, Sacramento, We focus on providing service for our clients as a key element in strengthening our long-term relationships. Our continual availability of high grade products in combination with our excellent pre-sale and after-sales service ensures strong competitiveness in an increasingly globalized market.

Timely delivery, strict implementation of the contract provisions of the goods, encountered special circumstances, but also actively cooperate, a trustworthy company!