Best China F Green Glass Pricelist - Jinjing Glass Processing Capabilities – Jinjing

Best China F Green Glass Pricelist - Jinjing Glass Processing Capabilities – Jinjing Detail:

Pre-processing

Glass pre-processing steps usually refers to cutting, drilling, edging, washing, drying. Jinjing has high performance fully automatic cutting lines from loading to breakout with any required shape and size.

Lisec Automatic Cutting Line

Bottero Automatic Cutting Line

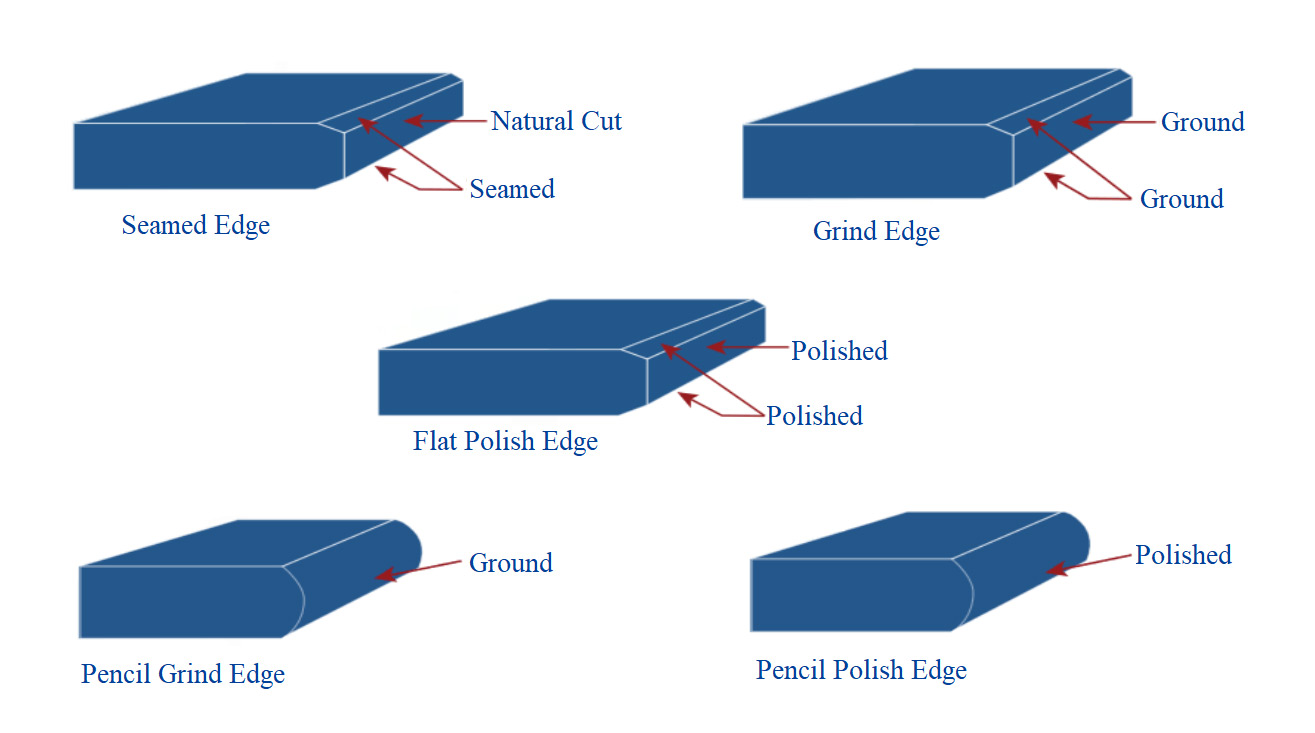

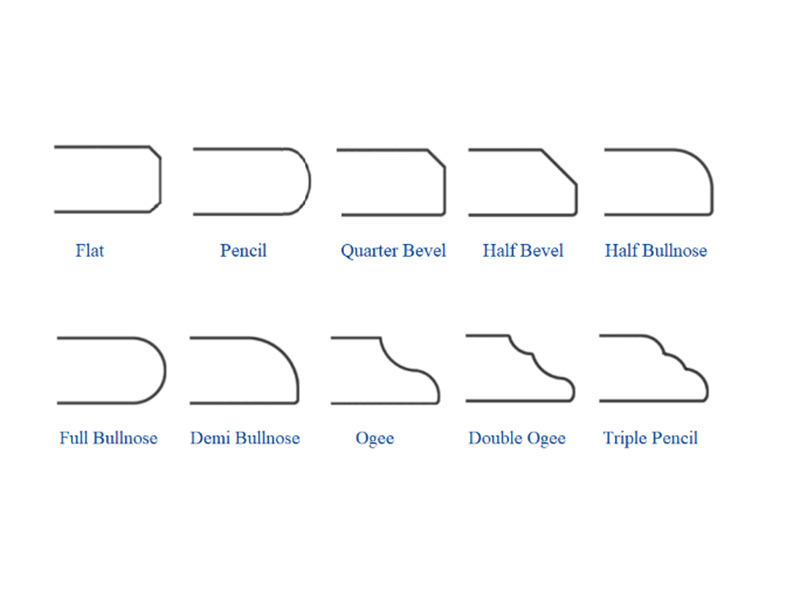

Finishing the sharp edges of cut glass enhances the glass through chip reduction, safe handling, and even custom design elements. Jinjing provide flat & pencil edging.

Bottero Grinding Line

Bentler Grinding Line

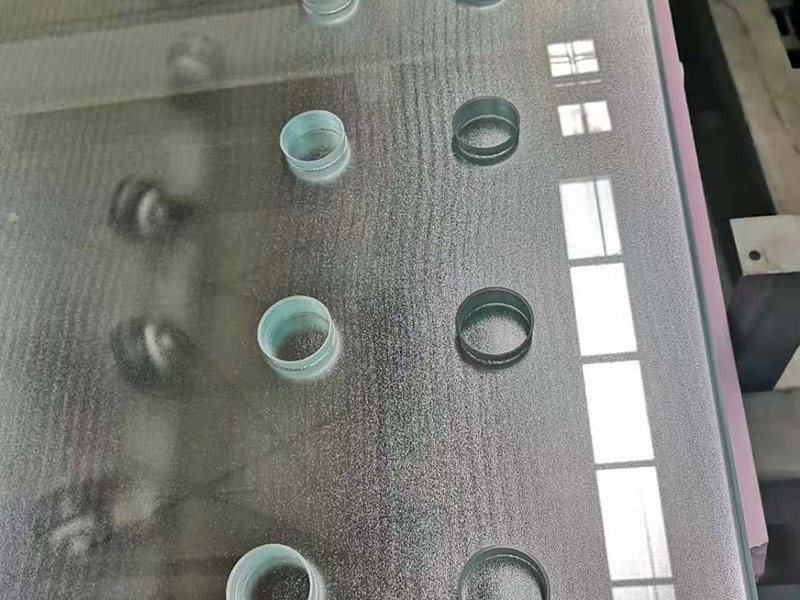

Whether you require drilling for glass doors, mirrors, furniture or something different, holes are essential elements that allow such products the ability to function properly for installation. Jinjing uses the most advanced equipment can meet the exact specifications for a variety of industries. Jinjing also provide customized glass shapes & edge working through waterjet cutting & CNC machines.

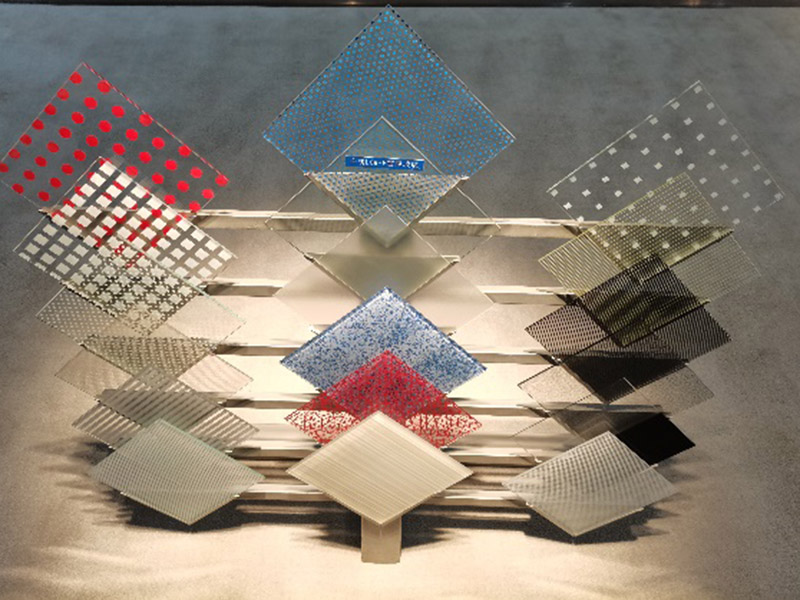

Printing & Painting

Printing & Painting glass is widely used in interior decoration, curtain wall, household appliances and other fields. Printing glass can perfectly reflect different cultural elements on buildings, and can provide architects with more ideas and methods. Printing glass has good weather resistance, never fade, scratch resistance, and UV protection. In North America, bird friendly glass is more widely used on high-rise building curtain walls, which can effectively protect the birds. Jinjing can supply silk printing, digital printing and painting.

Painting Line

Silk Printing Line

Digital Printing Line

Toughening & Heat Treating

Tempered or toughened glass is a type of safety glass processed by controlled thermal to increase its strength compared with normal glass. It is about four times stronger than annealed glass. Bent tempered glass is a curved safety glass which has been heated to a temperature where it softens up so that it can be molded into the desired shape. Heat Soak Test, or HST is a process that may expose nickel sulfide inclusions in tempered glass to minimize the risk of spontaneous breakages of heat-treated glass.

1) Jinjing has 8 tempering furnaces (except solar glass process bases) with yearly production capacity over 15 million ㎡, they are mainly for building glass, industrial glass.

Painting Line

Silk Printing Line

Digital Printing Line

Jinglass Toughening Furnace

TGGT Bent Toughening Furnace

2) Tempered glass manufactured by Jinjing ranks among the very top-quality products. It complies with European EN12150 and North American SGCC norms regarding flatness, strength, fragmentation, dimensions and tolerances etc.

3) The max sizes for tempered glass we can produce is 3300x10000mm. bent tempered glass with minimum radius 1000mm.

Production Process:

the annealed glass should be cut to the desired size firstly,then examined for imperfections that could cause breakage at any step during tempering. Then edges are grinded or polished, Next, the glass comes into a tempering oven which heats the glass to a temperature of more than 600 degrees Celsius. The glass then undergoes a high-pressure cooling procedure called “quenching.” And then high-pressure air blasts the surface of the glass in varying positions. Quenching cools the exterior surfaces of the glass much more quickly than the center. As the center of the glass cools, it tries to pull back from the exterior surfaces. As a result, the center remains in tension, and the exterior surfaces go into compression, which gives tempered glass its strength. For the bent tempered glass, the annealed glass is firstly heated to over 600 °C, the glass is moved within the furnace into the bending station, where it is bent to its target radius. We can make lengthwise bending and also crosswise bending. For Heat Soaked Test, Toughened glass is heated up to approximately 290 °C for a period of time specified in the applicable standard. Close to 99% glass panes with inclusions will be identified and suffer fracture in the heat soak test furnace.

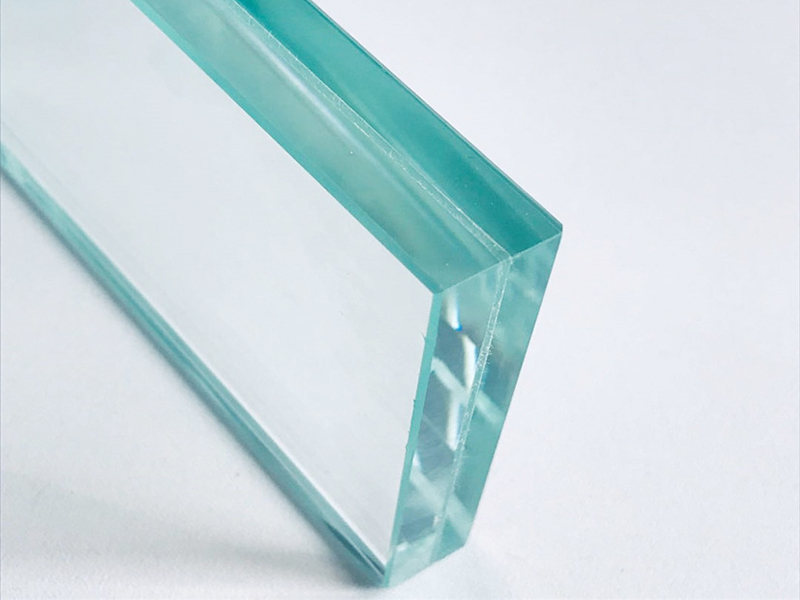

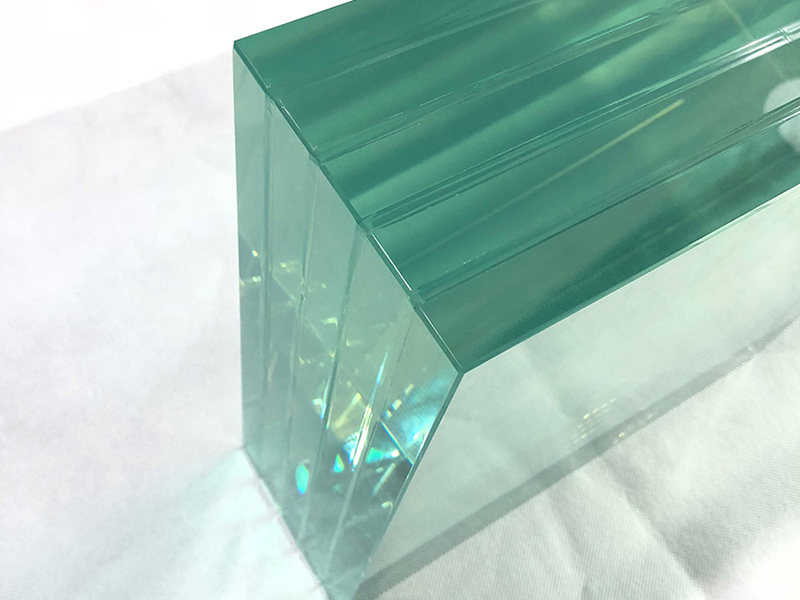

Laminating

Laminated glass is consisting of at least two single panes of glass which are joined together by a strong, tear-resistant polyvinyl butyral film (PVB). In the event of breaking, the interlayer keeps the layers of the glass bonded together reducing the risk of injury or harm. Laminated glass is normally used when there is a possibility of human impact or where the glass could fall and shatter.

Depending on the design needs, Jinjing offers laminated glass made with sheets of annealed, tempered, heat strengthened and coated glass which exhibits important structural performance and safety features along with other benefits. such as Safety / Security / Sound control/ Solar control, etc.

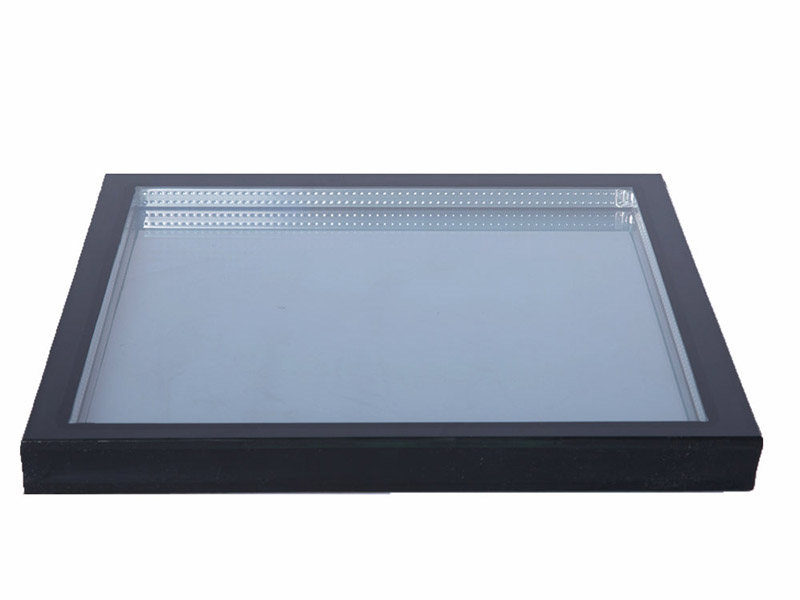

Insulating

The most exciting buildings built today are the energy efficient, environment friendly and thoroughly green. Insulating Glass Unit (commonly referred to as IGU or IG unit) with Low-E coating has already become the first choice of modern architectures. It is no longer just to shield from the storm, but more importantly to integrate multifunction of thermal insulation, energy saving, artistry, quietness and safety. It provides a comfortable living space in which people can enjoy the four seasons, energy efficiency, environment-friendliness and brightness. The energy-saving characteristic of Low-E IGU are majorly manifested in its heat insulation and heat preservation performances. The main measuring indexes are Shading Coefficient (SC) or Solar Heat Gain Coefficient (SHGC), and the thermal conductivity coefficient (U Value).

Insulating glass consists of two or more lites of glass sealed around the edges with an air space between, to form a single unit. Low-E coatings which cannot be exposed, and therefore cannot be used with monolithic glass, can be used inside the insulating unit where they are protected by the hermetically sealed space. JINJING insulating glass units are sealed with a primary seal and a secondary seal of silicone. Insulating glass products have a Limited Warranty for a period of (10) Years. JINJING insulating glass units are mainly made on Lisec automotive storage, cutting and insulating line imported from Austria. Annual Capacity is 0.8 million ㎡.

Jinjing offers multiple configurations of insulating glass units, more options for IGU. Insulating units also have more aesthetic possibilities to enhance the appearance and performance for your building, including silk-screen & digital print with rich colors, notches and holes if required, argon filling, curved as well as shaped IGU unit.

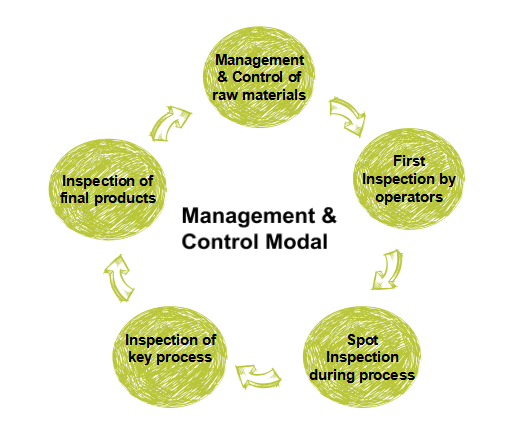

Quality Control System

Jinjing has a complete quality control system to ensure good quality for glass units, from raw material to cutting, edge grinding, tempering, laminating and insulating.

Related Certificates:

Product detail pictures:

Related Product Guide:

Persisting in "High top quality, Prompt Delivery, Aggressive Price", now we have established long-term cooperation with customers from the two overseas and domestically and get new and aged clients' large comments for Best China F Green Glass Pricelist - Jinjing Glass Processing Capabilities – Jinjing , The product will supply to all over the world, such as: Kenya, Amsterdam, Thailand, Our company always concentrate on the development of the international market. We now have a lot of customers in Russia , European countries, the USA, the Middle East countries and Africa countries. We always follow that quality is foundation while service is guarantee to meet all customers.

The company can keep up with the changes in this industry market, product updates fast and the price is cheap, this is our second cooperation, it's good.